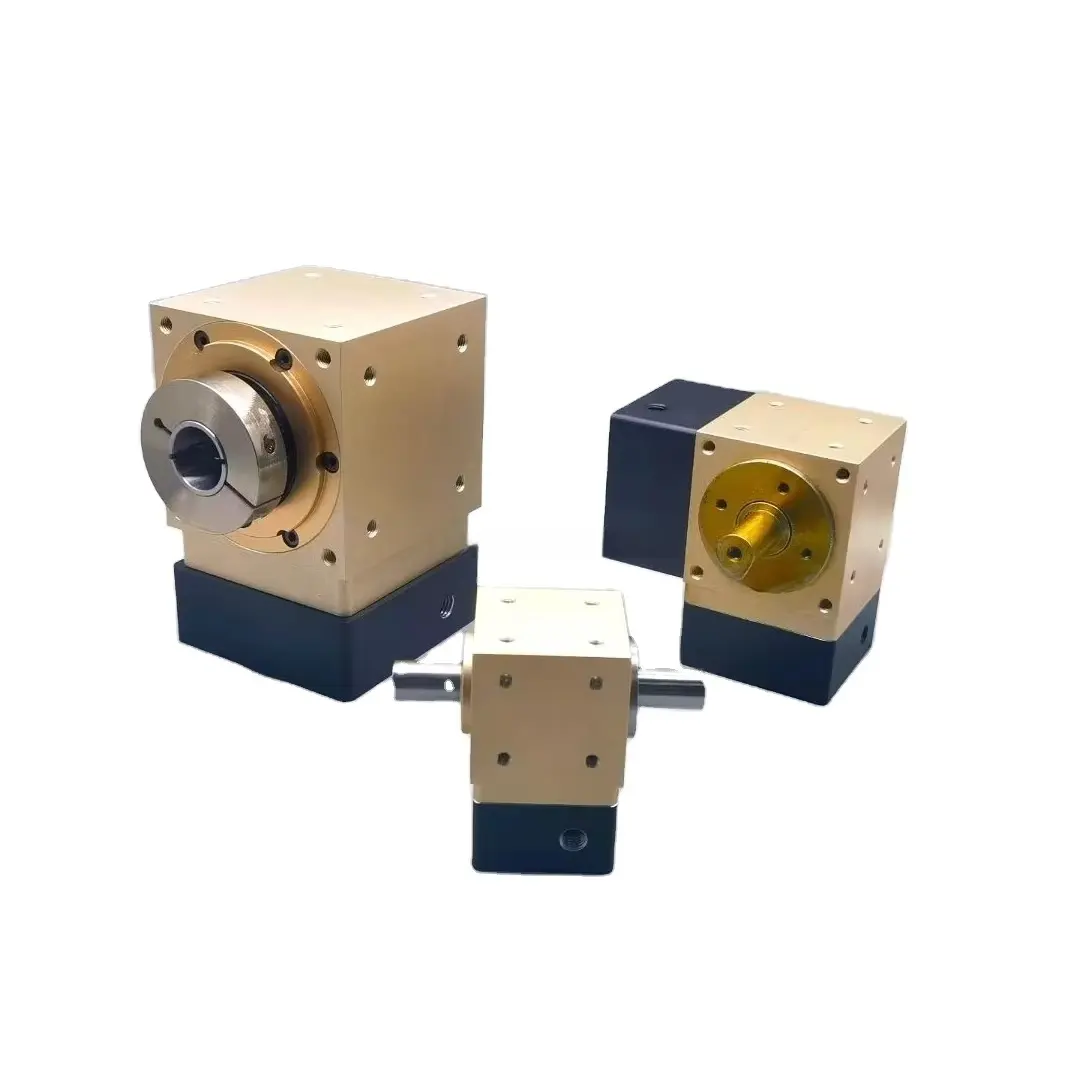

فهم قوة حلول التروس الصناعية الحديثة

في البيئة الصناعية التنافسية اليوم، فإن تحقيق أقصى قدر من كفاءة الآلات ليس خيارًا فحسب، بل ضرورة. يُعتبر المحول التروس الحلزوني مخفض التروس الحلزونية يُعتبر حجر الزاوية في أنظمة نقل الحركة الحديثة، ويقدم تحسينات ملحوظة في الأداء التشغيلي وكفاءة الطاقة. هذا الجهاز الهندسي المتطور يغيّر طريقة عمل الآلات، حيث يوفر انتقال قوة سلسًا مع تقليل كبير في الفاقد من الطاقة.

تعتمد الآلات الصناعية اعتمادًا كبيرًا على أنظمة نقل القدرة الدقيقة لكي تعمل بكفاءة. وقد برز مخفض التروس الحلزوني كمكون ثوري، يُحدث تغييرًا جذريًا في طريقة نقل القوة بين العناصر الميكانيكية. ومن خلال دمج أسنان حلزونية مصممة بعناية تتداخل تدريجيًا وتحافظ على تلامس مستمر، تضمن هذه المخفضات توزيعًا مثاليًا للقوة مع تقليل البلى وهدر الطاقة إلى الحد الأدنى.

العناصر الأساسية والتصميم المتميز

هندسة تصميم الأسنان المتقدمة

يتمثل نجاح مخفض التروس الحلزوني في تصميمه المتطور للأسنان. وعلى عكس التروس ذات الأسنان المستقيمة، فإن التروس الحلزونية تحتوي على أسنان مقطوعة بزاوية بالنسبة لسطح الترس. ويتيح هذا التكوين الزاوي تشابك عدة أسنان في آنٍ واحد، مما يوزع الحمل على منطقة تلامس أكبر. والنتيجة هي تشغيل أكثر سلاسة، وتقليل الضوضاء، وقدرة فائقة على تحمل الأحمال – وهي جميعها عوامل حاسمة في التطبيقات الصناعية.

لقد عززت تقنيات التصنيع الحديثة دقة ملفات الأسنان بشكل أكبر. ويضمن التصميم بمساعدة الحاسوب والعمليات المتقدمة للتشغيل الآلي هندسة أسنان مثالية، مما يُحسّن نمط التلامس بين التروس المتقابلة. وينعكس هذا المستوى من الدقة مباشرةً على تحسين الكفاءة، حيث تُقلَّل خسائر الطاقة الناتجة عن الاحتكاك والاهتزاز إلى أدنى حد.

الهياكل وأنظمة التزييت

يلعب هيكل العلبة في محمل التروس الحلزونية دورًا حيويًا في الحفاظ على الأداء التشغيلي المتميز. ويُصمم الهيكل باستخدام مواد عالية الجودة وبدقة تحملات عالية، حيث يوفر دعمًا وحماية ضروريين للمكونات الداخلية. وتشتمل التصاميم الحديثة على أنظمة إحكام معززة تمنع تسرب مادة التزييت وتحجب الملوثات، مما يضمن موثوقية طويلة الأمد.

لقد تطورت أنظمة التزييت في محولات السرعة الحلزونية تطورًا كبيرًا. وتتميز التصاميم الحديثة بأساليب متقدمة لتدوير الزيت تضمن وصول التزييت الكافي إلى جميع الأسطح المتلامسة. ويقلل هذا التغطية الشاملة للتزييت من الاحتكاك، ويساعد في إدارة توليد الحرارة، ويطيل عمر المحول الافتراضي.

المزايا الأداء والكفاءة

كفاءة نقل الطاقة الفائقة

يُظهر محول السرعة الحلزوني كفاءة استثنائية في نقل القدرة، حيث يحقق عادةً معدلات تزيد عن 95٪ لكل مرحلة. وينتج هذا الأداء العالي عن الدخول التدريجي لأسنان التروس، مما يقلل من فقدان الطاقة الناتج عن الاحتكاك والارتطام. كما أن تصميم الأسنان المائل يعزز أيضًا توزيع الحمل بشكل أفضل، مما يسمح بنقل عزم دوران أعلى دون المساس بالكفاءة.

عند مقارنتها بحلول نقل القوى الأخرى، تتميز علبة التروس الحلزونية بقدرتها على الحفاظ على كفاءة عالية تحت ظروف تحميل مختلفة. ويضمن هذا الأداء المتسق تشغيل الآلات عند مستويات مثلى، بغض النظر عن متطلبات الإنتاج المتغيرة أو ظروف التشغيل.

تقليل الضوضاء والاهتزاز

يُعد انخفاض الضوضاء والاهتزازات أثناء التشغيل من أبرز المزايا الناتجة عن استخدام علبة التروس الحلزونية. فالتداخل التدريجي للأسنان الحلزونية يلغي الصدمة المفاجئة المميزة للتروس ذات الأسنان المستقيمة، مما يؤدي إلى عملية تشغيل أكثر سلاسة وتقليل الإجهاد الواقع على مكونات الآلة.

تساهم مستويات الاهتزاز المنخفضة بشكل مباشر في تحسين كفاءة الآلة من خلال تقليل هدر الطاقة الناتج عن التذبذب الميكانيكي. علاوةً على ذلك، يعني الاهتزاز الأقل تعرّض المحامل والختمات والمكونات الحرجة الأخرى لارتداء أقل، مما يؤدي إلى تقليل متطلبات الصيانة وزيادة عمر المعدات.

استراتيجيات التنفيذ والصيانة

الاختيار والتقدير الأمثلان

يتطلب اختيار المخفض اللولبي الصحيح مراعاة دقيقة لعوامل مختلفة تشمل نسبة التخفيض المطلوبة، وسرعة الدخل، والعزم الناتج، ومعامل الخدمة. يقوم المهندسون المحترفون بتحليل هذه المعايير للتأكد من أن المخفض المختار يلائم متطلبات التطبيق بدقة. ويُعد هذا التطابق الدقيق أمرًا بالغ الأهمية لتحقيق أقصى قدر من المكاسب في الكفاءة.

تتيح أدوات واختيار الحالية حسابات دقيقة لمعاير الأداء، مما يساعد على منع التصنيف بأقل أو أكثر من اللازم للمخفضات. ويضمن هذا الدقة في الاختيار أن الوحدة المثبتة تعمل ضمن نطاق كفاءتها الأمثل، ما يزيد من توفير الطاقة والفوائد التشغيلية.

بروتوكولات الصيانة الوقائية

للحفاظ على الكفاءة القصوى، تتطلب علب تروس المخفض الحلزوني اهتمامًا منهجيًا بالصيانة. يساعد التحليل المنتظم للزيت في مراقبة حالة المكونات الداخلية وجودة التشحيم. ويمكن لأنظمة مراقبة درجة الحرارة أن تكتشف المشكلات المحتملة قبل أن تؤدي إلى فقدان الكفاءة أو تلف المعدات.

غالبًا ما تتضمن برامج الصيانة المتقدمة تحليل الاهتزازات والتصوير الحراري لمراقبة أداء المخفضات بمرور الوقت. تساعد هذه التقنيات التنبؤية في الحفاظ على مستويات الكفاءة المثلى، مع منع الأعطال غير المتوقعة والإصلاحات المكلفة.

اتجاهات المستقبل والابتكارات

أنظمة المراقبة الذكية

يمثل دمج أجهزة الاستشعار الذكية ونُظم المراقبة المرحلة التالية من تطور تقنية مخفضات التروس الحلزونية. توفر هذه النظم بيانات فورية حول المعايير التشغيلية مثل درجة الحرارة والاهتزاز وحالة الزيت. تتيح هذه المعلومات إدارة الصيانة التنبؤية والكفاءة المثلى من خلال اكتشاف المشكلات المحتملة في مراحلها المبكرة.

أصبح التوافق مع الصناعة 4.0 أمرًا متزايد الأهمية في تصميمات مخفضات التروس الحديثة. يمكن للنُظم المتصلة تعديل المعايير التشغيلية تلقائيًا بناءً على ظروف الحمل وبيانات الأداء، مما يضمن الحد الأقصى من الكفاءة تحت ظروف متغيرة.

تطورات التصميم المستدام

تدفع الاعتبارات البيئية الابتكارات في تصميم محركات التروس الحلزونية. تركز المواد والعمليات التصنيعية الجديدة على تقليل الأثر البيئي مع الحفاظ على مستويات الكفاءة أو تحسينها. وتساهم التصاميم الموفرة للطاقة والمواد التشحيمية الصديقة للبيئة في خفض تكاليف التشغيل والأثر البيئي.

تتواصل الأبحاث في تقنيات الطلاء المتقدمة ومعالجات السطح التي يمكن أن تقلل من الاحتكاك وتحسّن الكفاءة بشكل أكبر. تعد هذه التطورات بتوسيع حدود ما هو ممكن من حيث كفاءة نقل القدرة.

الأسئلة الشائعة

ما هي الفترة الزمنية الموصى بها للصيانة لمحول تروس حلزوني؟

تتراوح فترات الصيانة الدورية عادةً بين 2500 و5000 ساعة تشغيل، حسب التطبيق وظروف التشغيل. وتشمل هذه الفترات تغيير الزيت، وفحص الختم، وإجراء فحوصات عامة للأداء. ومع ذلك، يجب تحديد جداول الصيانة المحددة بناءً على توصيات الشركة المصنعة وظروف التشغيل الفعلية.

ما هي المدة التي يمكن أن يستمر بها محمل تروس حلزوني قبل أن يحتاج إلى استبدال؟

مع الصيانة المناسبة وظروف التشغيل الجيدة، يمكن لمحول تروس حلزوني عالي الجودة أن يستمر لمدة 20 عامًا أو أكثر. وتعتمد المدة الفعلية للخدمة على عوامل مثل ظروف التحميل وممارسات الصيانة والعوامل البيئية. ويمكن للرصد المنتظم والصيانة أن يمددا عمر التشغيل بشكل كبير.

هل يمكن استبدال محولات التروس المستقيمة الحالية بمحولات تروس حلزونية؟

في معظم الحالات، نعم. غالبًا ما يتطلب التحديث إلى محول تروس حلزوني تعديلات طفيفة على الأنظمة الحالية ويمكنه تحقيق تحسينات فورية في الكفاءة. ومع ذلك، من المهم استشارة متخصصين في الهندسة للتأكد من الحجم المناسب والتوافق مع التطبيق المحدد الخاص بك.

ما هي العلامات الرئيسية لفقدان الكفاءة في محول تروس حلزوني؟

تشمل المؤشرات الشائعة ارتفاع درجة حرارة التشغيل، ومستويات الضوضاء غير المعتادة، والاهتزاز المفرط، واستهلاك الطاقة العالي. يمكن أن يساعد الرصد المنتظم لهذه المعايير في تحديد فقدان الكفاءة مبكرًا ومنع تطور مشكلات أكثر جدية.