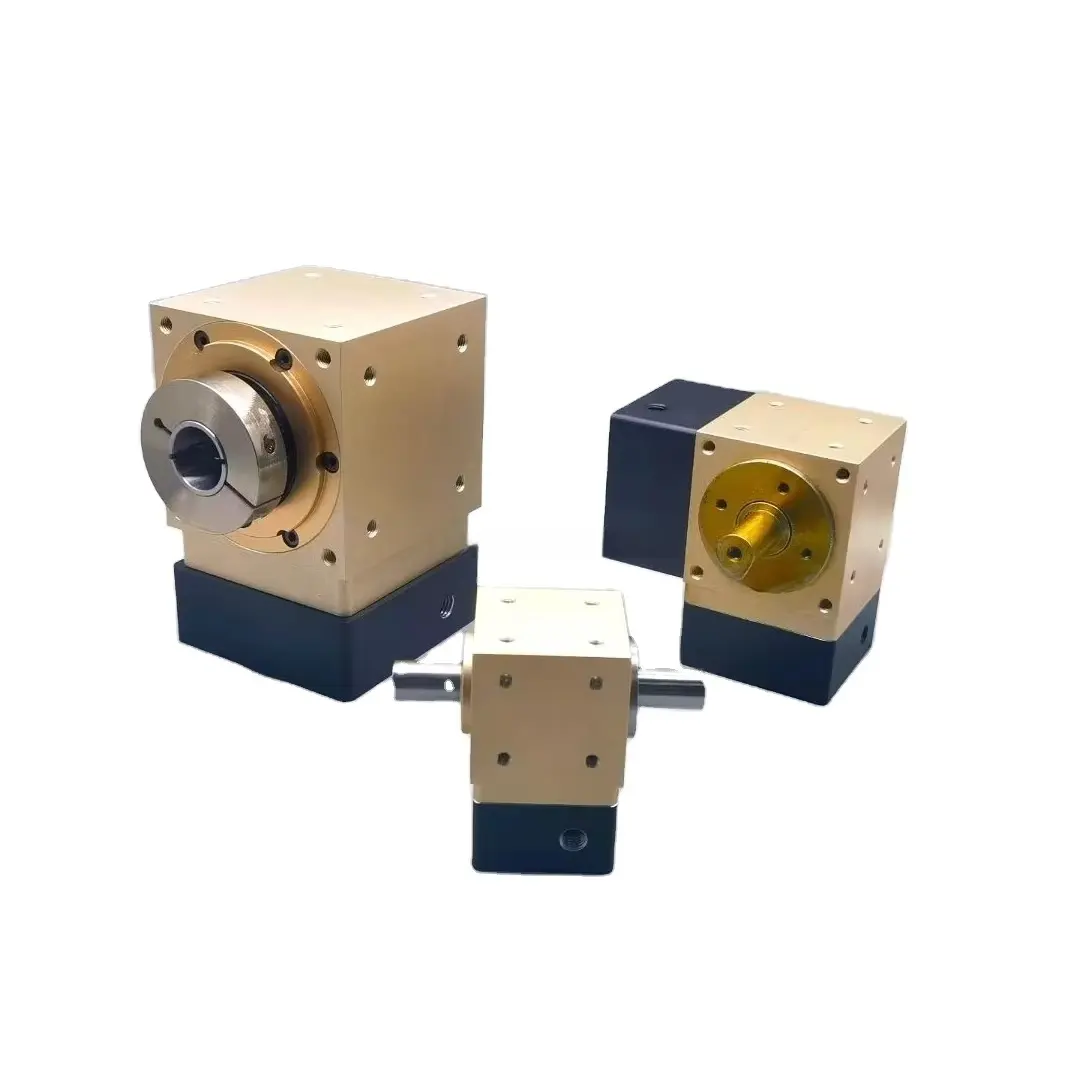

हेलिकल गियर रिडक्शन सिस्टम के पीछे की शक्ति को समझना

औद्योगिक मशीनरी और पावर ट्रांसमिशन की दुनिया में, हेलिकल गियर रिड्यूसर इंजीनियरिंग उत्कृष्टता का प्रमाण हैं। ये जटिल यांत्रिक घटक विभिन्न उद्योगों में मशीन प्रदर्शन को अनुकूलित करने में एक महत्वपूर्ण भूमिका निभाते हैं। उच्च गति, कम टोक़ इनपुट को कम गति, उच्च टोक़ आउटपुट में बदलकर, एक हेलिकल गियर रिड्यूसर उपकरणों को यांत्रिक प्रक्रियाओं पर सटीक नियंत्रण बनाए रखते हुए अधिक कुशलता से संचालित करने में सक्षम बनाता है।

हेलिकल गियर रिड्यूसर के विशिष्ट डिज़ाइन, जिसमें गियर के सामने के हिस्से के कोण पर दांत काटे जाते हैं, पारंपरिक स्पर गियर की तुलना में अधिक सुचारु संलग्नक की अनुमति देता है और शांत संचालन। गियर रिडक्शन के इस नवीन दृष्टिकोण से न केवल प्रदर्शन में सुधार होता है बल्कि कम घिसावट और बेहतर भार वितरण के माध्यम से उपकरण के जीवन को भी बढ़ाया जाता है।

हेलिकल के मुख्य लाभ गियर रिड्यूसर प्रौद्योगिकी

बेहतर संचालन दक्षता

यांत्रिक शक्ति संचरण के मामले में, दक्षता सर्वोच्च प्राथमिकता है। एक हेलिकल गियर रिड्यूसर उत्कृष्ट शक्ति स्थानांतरण क्षमताओं प्रदान करके इस पहलू में उत्कृष्टता प्राप्त करता है। कोणीय दांत डिज़ाइन सुनिश्चित करता है कि एक साथ कई दांत संलग्न हों, जिसके परिणामस्वरूप बेहतर भार वितरण और ऊर्जा की कम हानि होती है। यह बढ़ा हुआ संपर्क अनुपात सुचारु संचालन और समग्र प्रणाली दक्षता में सुधार की ओर ले जाता है।

आधुनिक हेलिकल गियर रिड्यूसर प्रति स्टेज 98% तक की दक्षता रेटिंग प्राप्त कर सकते हैं, जो कई वैकल्पिक पावर ट्रांसमिशन समाधानों की तुलना में काफी अधिक है। इस उत्कृष्ट दक्षता का सीधा अर्थ है औद्योगिक अनुप्रयोगों के लिए कम ऊर्जा खपत और कम संचालन लागत।

शोर कम करना और सुलभ कार्यवाही

हेलिकल गियर रिड्यूसर को लागू करने के सबसे महत्वपूर्ण लाभों में से एक संचालन के दौरान शोर में नाटकीय कमी है। झुके हुए दांतों के धीरे-धीरे संलग्न होने के कारण सीधे कटे गियर की तुलना में शांत संचालन होता है। यह विशेषता हेलिकल गियर रिड्यूसर को उन अनुप्रयोगों के लिए आदर्श बनाती है जहां शोर कम करना महत्वपूर्ण है, जैसे निर्माण सुविधाओं में जहां कर्मचारी सुविधा प्राथमिकता होती है।

सुचारु संचालन से कंपन के स्तर में कमी भी होती है, जिससे संबद्ध उपकरणों के जीवनकाल को बढ़ाने में मदद मिल सकती है और सटीक निर्माण प्रक्रियाओं में उत्पादन की गुणवत्ता में सुधार हो सकता है।

प्रदर्शन को बढ़ावा देने वाली डिज़ाइन विशेषताएं

उन्नत दांत ज्यामिति

एक हेलिकल गियर रिड्यूसर की सफलता इसकी परिष्कृत दांत प्रारूप में निहित है। हेलिकल कट से संयुग्मित गियर्स के बीच संपर्क क्षेत्र बढ़ जाता है, जो दांत के फलक पर भार को अधिक समान रूप से वितरित करने में सहायता करता है। यह डिज़ाइन विशेषता न केवल शक्ति संचरण दक्षता में सुधार करती है, बल्कि गियर दांतों पर होने वाले घर्षण को भी कम करती है, जिससे सेवा आयु बढ़ती है और रखरखाव की आवश्यकता कम होती है।

आधुनिक निर्माण तकनीक दांत प्रोफाइल पर सटीक नियंत्रण रखने की अनुमति देती है, जिससे इष्टतम संपर्क पैटर्न और न्यूनतम बैकलैश सुनिश्चित होता है। यह सटीकता स्वचालित प्रणालियों में चिकने संचालन और अधिक सटीक स्थिति नियंत्रण में योगदान देती है।

थर्मल प्रबंधन क्षमताएँ

ऊष्मा उत्पादन गियर रिड्यूसर के प्रदर्शन में एक महत्वपूर्ण कारक है। हेलिकल गियर रिड्यूसर को उन्नत तापीय प्रबंधन क्षमताओं के साथ डिज़ाइन किया गया है, जिसमें अनुकूलित आवास डिज़ाइन और उन्नत स्नेहन प्रणाली जैसी विशेषताएं शामिल हैं। ये तत्व भारी भार और निरंतर संचालन के तहत भी इष्टतम संचालन तापमान बनाए रखने में साथ-साथ काम करते हैं।

थर्मल ऊर्जा के प्रभावी प्रबंधन से आवश्यकता से पहले होने वाले घिसाव और भिन्न परिचालन स्थितियों में सुसंगत प्रदर्शन सुनिश्चित करने में मदद मिलती है। इस विश्वसनीयता का विशेष महत्व उन अनुप्रयोगों में होता है जहाँ अप्रत्याशित बंदी के कारण उल्लेखनीय उत्पादन हानि हो सकती है।

अधिकतम लाभ के लिए कार्यान्वयन रणनीतियाँ

उचित माप और चयन

हेलिकल गियर रिड्यूसर के लाभों को अधिकतम करने के लिए, उचित आकार निर्धारण आवश्यक है। इसमें इनपुट गति, आउटपुट टोर्क आवश्यकताओं, ड्यूटी चक्र और पर्यावरणीय स्थितियों जैसे कारकों पर सावधानीपूर्वक विचार शामिल है। एक सही आकार निर्धारित रिड्यूसर अपनी इष्टतम दक्षता सीमा के भीतर संचालित होगा जबकि पर्याप्त सेवा जीवन और विश्वसनीय प्रदर्शन प्रदान करेगा।

चयन प्रक्रिया के दौरान अनुभवी इंजीनियरों के साथ काम करने से यह सुनिश्चित करने में मदद मिल सकती है कि चुना गया हेलिकल गियर रिड्यूसर वर्तमान आवश्यकताओं के साथ-साथ भावी परिचालन आवश्यकताओं को भी पूरा करे। यह आगे की ओर देखने वाली दृष्टिकोण भविष्य में महंगे अपग्रेड या प्रतिस्थापन से बचाव करने में सहायता करती है।

रखरखाव के सर्वश्रेष्ठ अभ्यास

जबकि हेलिकल गियर रिड्यूसर अपनी विश्वसनीयता के लिए जाने जाते हैं, इष्टतम प्रदर्शन और लंबी आयु प्राप्त करने के लिए उचित रखरखाव महत्वपूर्ण है। नियमित तेल विश्लेषण, कंपन निगरानी और दृश्य निरीक्षण से गंभीर समस्याओं में बदलने से पहले संभावित समस्याओं की पहचान करने में मदद मिल सकती है। निर्माता द्वारा अनुशंसित रखरखाव कार्यक्रम और प्रक्रियाओं का पालन करने से निरंतर कुशल संचालन सुनिश्चित होता है।

एक निवारक रखरखाव कार्यक्रम लागू करना जिसमें प्रमुख प्रदर्शन संकेतकों की नियमित निगरानी शामिल हो, रखरखाव अंतराल को अनुकूलित करने और अप्रत्याशित विफलताओं को रोकने में मदद कर सकता है। रखरखाव के इस प्रो-एक्टिव दृष्टिकोण से संचालन लागत में काफी कमी आ सकती है, जबकि उपकरण का अधिकतम समय तक संचालन जारी रखा जा सकता है।

अक्सर पूछे जाने वाले प्रश्न

हेलिकल गियर रिड्यूसर अन्य प्रकारों की तुलना में अधिक कुशल क्यों होते हैं?

हेलिकल गियर रिड्यूसर अपने कोणीय दांत डिज़ाइन के माध्यम से उच्च दक्षता प्राप्त करते हैं, जो बड़े सतह संपर्क क्षेत्र और सुचारु शक्ति संचरण प्रदान करता है। इसके परिणामस्वरूप सीधे कटे गियर की तुलना में घर्षण के माध्यम से कम ऊर्जा की हानि और बेहतर भार वितरण होता है।

मैं हेलिकल गियर रिड्यूसर के लिए कितने समय तक आयुष्य की अपेक्षा कर सकता हूँ?

उचित रखरखाव और संचालन की स्थिति के साथ, एक गुणवत्तापूर्ण हेलिकल गियर रिड्यूसर 15-20 वर्ष या उससे अधिक समय तक चल सकता है। हालाँकि, वास्तविक सेवा आयु लोडिंग स्थितियों, रखरखाव प्रथाओं और संचालन वातावरण जैसे कारकों पर निर्भर करती है।

हेलिकल गियर रिड्यूसर के लिए प्रमुख रखरखाव आवश्यकताएँ क्या हैं?

आवश्यक रखरखाव में नियमित तेल परिवर्तन, तेल की गुणवत्ता और स्तर की निगरानी, असामान्य शोर या कंपन की जाँच, सील और बेयरिंग का निरीक्षण, और उचित संरेखण सुनिश्चित करना शामिल है। इष्टतम प्रदर्शन और लंबे जीवन के लिए निर्माता दिशानिर्देशों का पालन करना महत्वपूर्ण है।