Selecting the Perfect Helical Gear Motor for Your Industrial Applications

Choosing the right helical gear motor is essential for ensuring that machinery operates efficiently, reliably, and with optimal performance. Helical gear motors combine the advantages of helical gearing with integrated motor systems to offer smooth torque transmission, compact design, and high durability. Whether upgrading existing equipment or designing new systems, understanding the key factors involved in selecting a gear motor can save time, reduce costs, and improve operational outcomes. This blog explores critical considerations and practical tips for choosing helical gear motors tailored to your specific needs.

Understanding Basic Gear Motor Specifications

Power Rating and Torque Requirements

One of the first considerations when selecting a gear motor is understanding the power output and torque requirements of your application. Different industrial machines demand varying levels of torque to perform tasks effectively. Gear motors are rated based on their power capacity, often measured in kilowatts or horsepower, and torque output in Newton-meters or pound-feet.

Knowing the peak and continuous torque requirements helps in choosing a gear motor that can handle the mechanical loads without premature wear or failure. It is also important to consider starting torque versus running torque, especially in applications with frequent starts and stops.

Speed and Gear Ratio

The operating speed of the helical gear motor must match the requirements of the driven equipment. Gear ratio directly affects the output speed and torque. Higher gear ratios reduce speed but increase torque, while lower ratios do the opposite. Selecting the right ratio ensures the motor delivers power efficiently at the desired speed.

Matching the gear motor’s speed range to the application can improve energy efficiency and prolong the life of the equipment. Variable speed drives can further enhance flexibility but should be compatible with the gear motor’s design.

Mechanical and Environmental Considerations

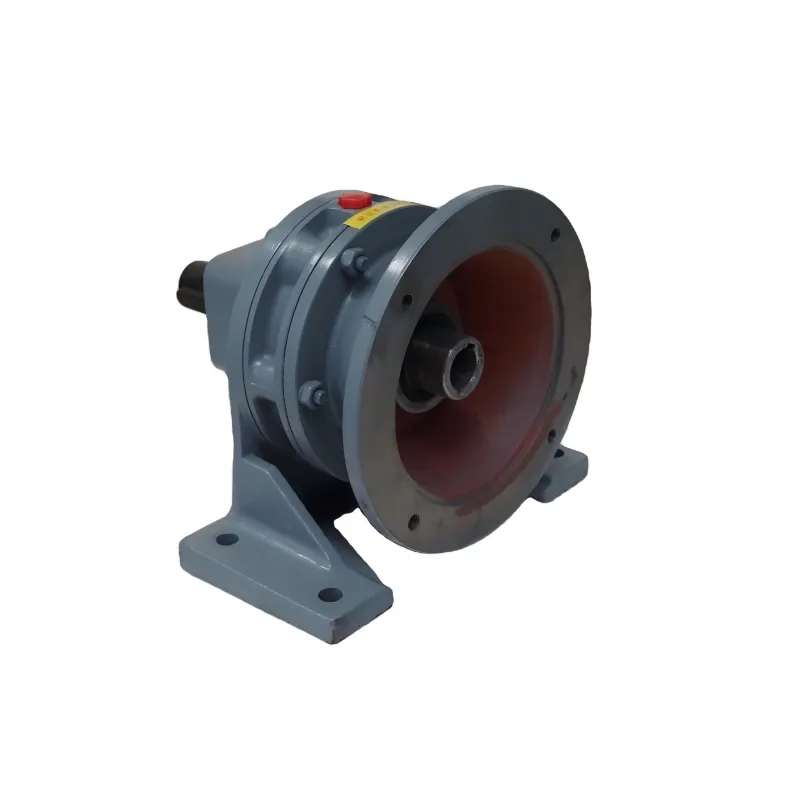

Mounting Configuration and Space Constraints

Industrial spaces often impose physical constraints that influence gear motor selection. Mounting style—such as foot-mounted, flange-mounted, or shaft-mounted—determines how the gear motor integrates with existing machinery.

Choosing a gear motor with the appropriate mounting option facilitates easy installation and alignment. Additionally, the physical footprint of the gear motor matters, especially in compact or mobile equipment. Compact designs with helical gearing help optimize space without sacrificing performance.

Operating Environment and Durability

Gear motors deployed in harsh environments require features like corrosion-resistant coatings, sealed housings, and protection against dust, moisture, or chemicals. Understanding the operating conditions is crucial for selecting a gear motor with the right ingress protection (IP) rating and materials.

Temperature ranges, exposure to vibrations, and shock loads also impact gear motor longevity. Selecting a unit designed for these conditions helps avoid unplanned downtime and costly repairs.

Efficiency and Energy Considerations

Energy Efficiency Ratings and Power Consumption

Energy-efficient gear motors contribute to reducing operational costs and environmental impact. Modern helical gear motors are engineered to minimize friction losses and operate at high efficiencies across various load conditions.

Evaluating energy consumption over the expected service life is critical, especially in continuous or high-duty applications. Selecting gear motors with efficient design and quality components can lead to significant savings on power bills.

Heat Dissipation and Cooling Options

Efficient heat dissipation is important for maintaining the gear motor’s performance and extending its lifespan. Overheating can degrade lubricants and damage internal components.

Some gear motors include integrated cooling fins, fans, or liquid cooling options, depending on power rating and usage. Considering the thermal management requirements of your application helps ensure reliable operation.

Maintenance and Serviceability

Lubrication and Maintenance Intervals

Gear motors require proper lubrication to function smoothly. Understanding the lubrication type—grease or oil-based—and maintenance intervals can help maintain optimal performance.

Selecting gear motors with accessible lubrication points and clear maintenance instructions reduces downtime. Some units feature sealed-for-life lubrication, which lowers the frequency of service interventions.

Ease of Inspection and Part Replacement

When choosing a gear motor, consider the ease of inspection and the availability of replacement parts. Industrial machinery benefits from components that can be quickly serviced or swapped, minimizing operational disruptions.

Gear motors with modular designs and standardized parts simplify maintenance processes and improve overall reliability.

Integration with Control Systems

Compatibility with Variable Frequency Drives (VFDs)

Many modern industrial processes require variable speed operation for process flexibility and energy savings. Ensuring the helical gear motor is compatible with VFDs or other speed control systems is essential for seamless integration.

Gear motors designed for VFD operation maintain consistent torque output and withstand varying loads without excessive wear.

Sensor and Monitoring Capabilities

Integration of sensors for temperature, vibration, or load monitoring can enhance predictive maintenance and prevent unexpected failures. Selecting gear motors that support condition monitoring helps optimize uptime and reduce maintenance costs.

Connected gear motors fit well in Industry 4.0 environments, supporting remote diagnostics and performance tracking.

Application-Specific Factors

Load Type and Duty Cycle

The nature of the load—whether constant, shock, or variable—and the duty cycle directly influence gear motor selection. Heavy shock loads require gear motors built with robust gearing and bearings, while variable loads benefit from flexible torque capabilities.

Understanding the operating pattern enables choosing gear motors with appropriate service factors and thermal ratings.

Noise and Vibration Sensitivity

In environments sensitive to noise or vibration, such as food processing or medical manufacturing, the smooth operation of helical gear motors offers advantages. Selecting units with noise-reducing features and vibration-dampening design helps maintain workplace safety and compliance with regulations.

Final Steps Before Purchase

Verifying Manufacturer Support and Warranty

Choosing gear motors from suppliers who provide technical support, documentation, and warranty coverage ensures peace of mind. Manufacturer responsiveness can be vital for troubleshooting and optimizing performance over time.

Requesting Samples or Testing

When possible, obtaining sample units or conducting pilot tests helps validate gear motor performance in real-world conditions. This practical evaluation reduces risk before committing to large-scale implementation.

FAQ

What factors most affect the lifespan of a helical gear motor?

Operating conditions, load profiles, lubrication quality, and maintenance practices all influence gear motor lifespan. Proper selection and upkeep minimize premature failures.

How do I determine the correct gear ratio for my application?

Analyze the required output speed and torque. The gear ratio should match these requirements while considering motor speed and desired efficiency.

Are all helical gear motors suitable for variable speed operation?

Not all, but many modern helical gear motors are designed to work with variable frequency drives. Confirm compatibility with your specific control system.

What maintenance is typically required for gear motors?

Regular lubrication checks, visual inspections, and alignment verification are common. Some gear motors have sealed lubrication, reducing maintenance needs.

Table of Contents

- Selecting the Perfect Helical Gear Motor for Your Industrial Applications

- Understanding Basic Gear Motor Specifications

- Mechanical and Environmental Considerations

- Efficiency and Energy Considerations

- Maintenance and Serviceability

- Integration with Control Systems

- Application-Specific Factors

- Final Steps Before Purchase

- FAQ