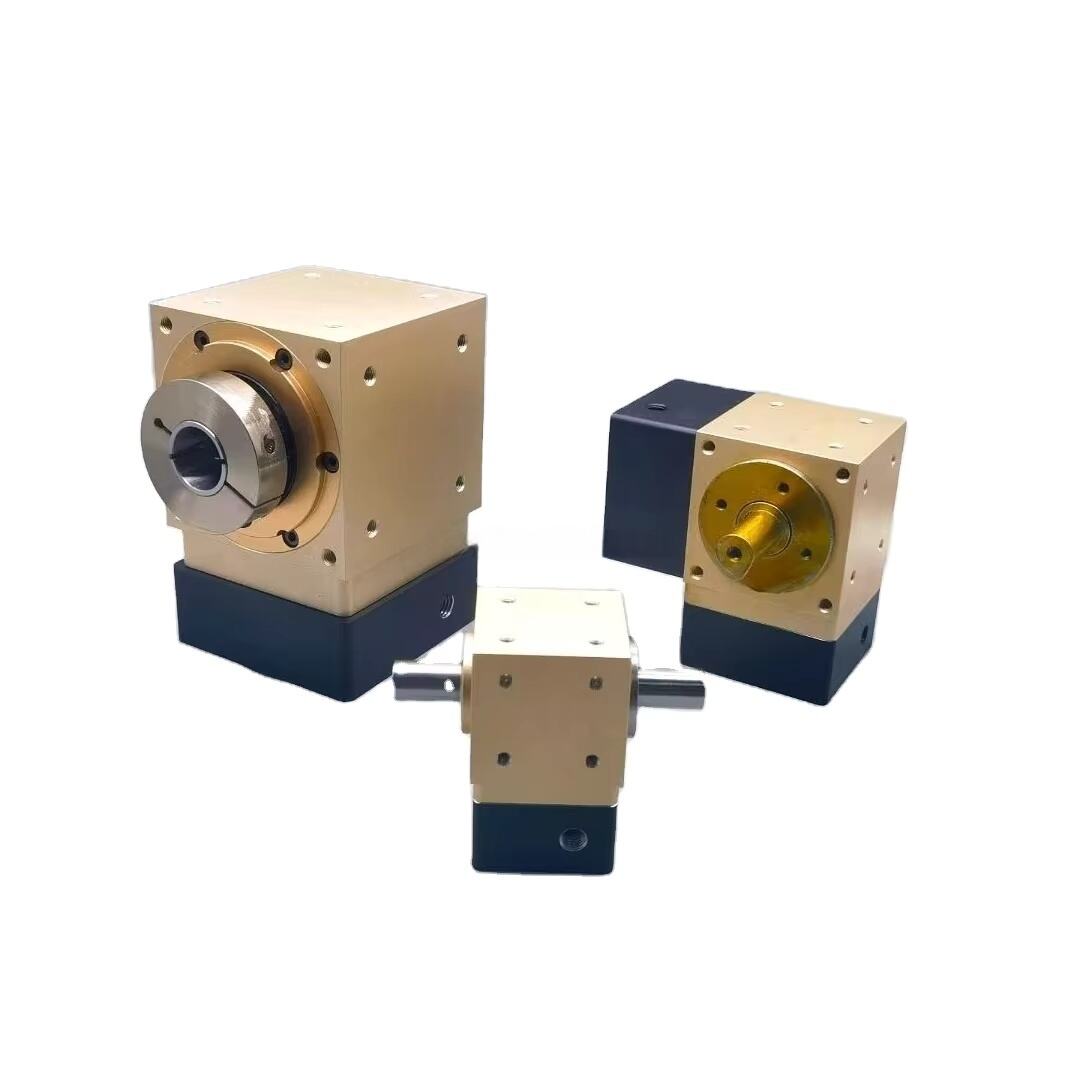

speed reduction gearbox

A speed reduction gearbox is an essential mechanical device that efficiently manages rotational speed and torque in various industrial applications. This sophisticated system consists of multiple gears working in harmony to decrease the output speed while simultaneously increasing torque, making it invaluable in numerous industrial processes. The gearbox employs precision engineered gear sets, typically including helical, spur, or planetary configurations, housed within a robust casing that ensures optimal lubrication and protection from external elements. These gearboxes are designed to handle high power transmission requirements while maintaining mechanical efficiency, often achieving reduction ratios from 5:1 to 70:1 or higher, depending on the specific application needs. The internal components are manufactured from high grade materials, such as hardened steel, ensuring durability and reliable performance under demanding conditions. Modern speed reduction gearboxes often incorporate advanced features like thermal management systems, precision bearings, and specialized sealing mechanisms that contribute to extended service life and reduced maintenance requirements. These units play a crucial role in various industries, from manufacturing and mining to renewable energy and material handling equipment, where precise speed control and high torque output are essential for operational success.