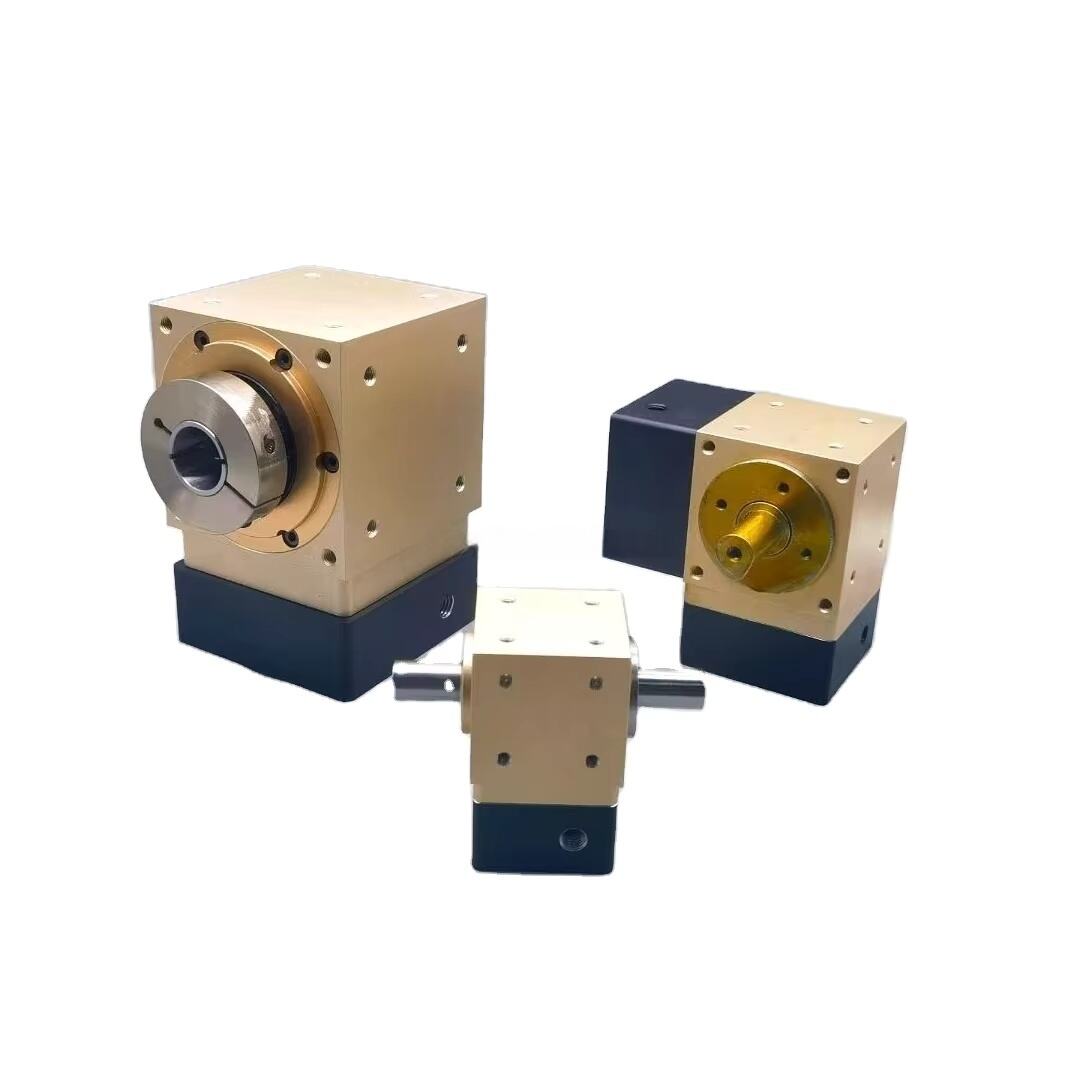

worm reduction gearbox

A worm reduction gearbox is a sophisticated power transmission device that combines a worm gear and a worm wheel to achieve significant speed reduction and torque multiplication. This mechanical system consists of a threaded shaft (worm) that meshes with a larger toothed wheel, creating a highly efficient means of power transfer. The design allows for substantial gear ratios, typically ranging from 5:1 to 100:1, making it ideal for applications requiring precise speed control and high torque output. The worm gear's unique helical thread pattern enables smooth, quiet operation while maintaining excellent load distribution across multiple teeth simultaneously. These gearboxes excel in converting high-speed, low-torque input into low-speed, high-torque output, making them essential in various industrial applications. The system's compact design offers space efficiency while providing reliable performance in both continuous and intermittent operation scenarios. Modern worm reduction gearboxes often incorporate advanced materials and precision manufacturing techniques, ensuring optimal efficiency and extended service life. They are commonly found in conveyor systems, elevators, material handling equipment, and various manufacturing processes where controlled speed reduction is crucial.