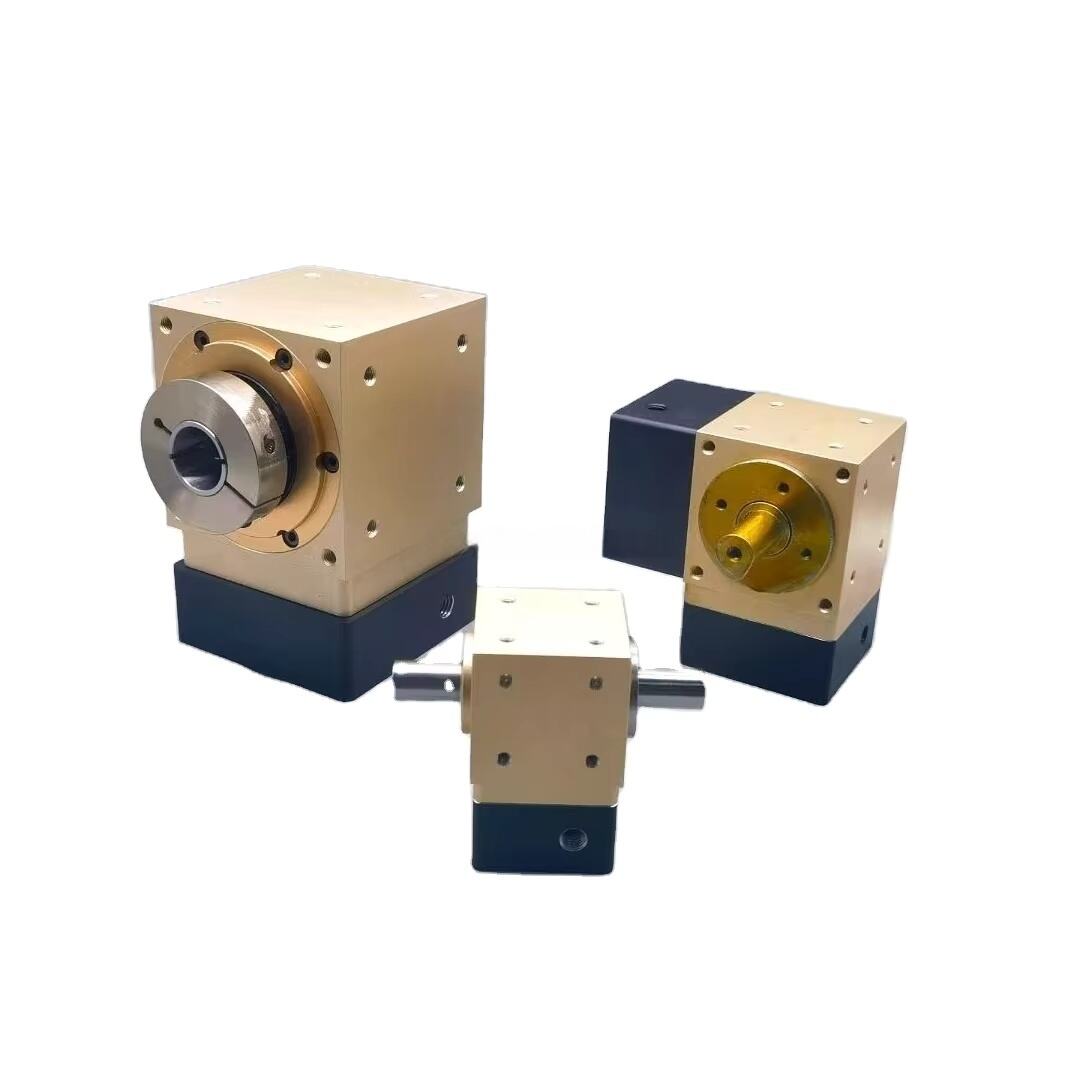

Versatile Mounting and Integration Options

The right angle gear reducer's adaptable mounting system provides unprecedented flexibility in installation and integration across various applications. The design incorporates multiple mounting configurations, including foot mounting, flange mounting, and shaft mounting options, allowing for seamless integration into existing machinery or new installations. The standardized input and output interfaces accommodate a wide range of shaft sizes and configurations, while the robust housing design ensures stable operation regardless of mounting orientation. This versatility is further enhanced by the availability of various shaft options, including solid, hollow, and shrink disc configurations, making it possible to adapt the reducer to specific application requirements without compromising performance or reliability.