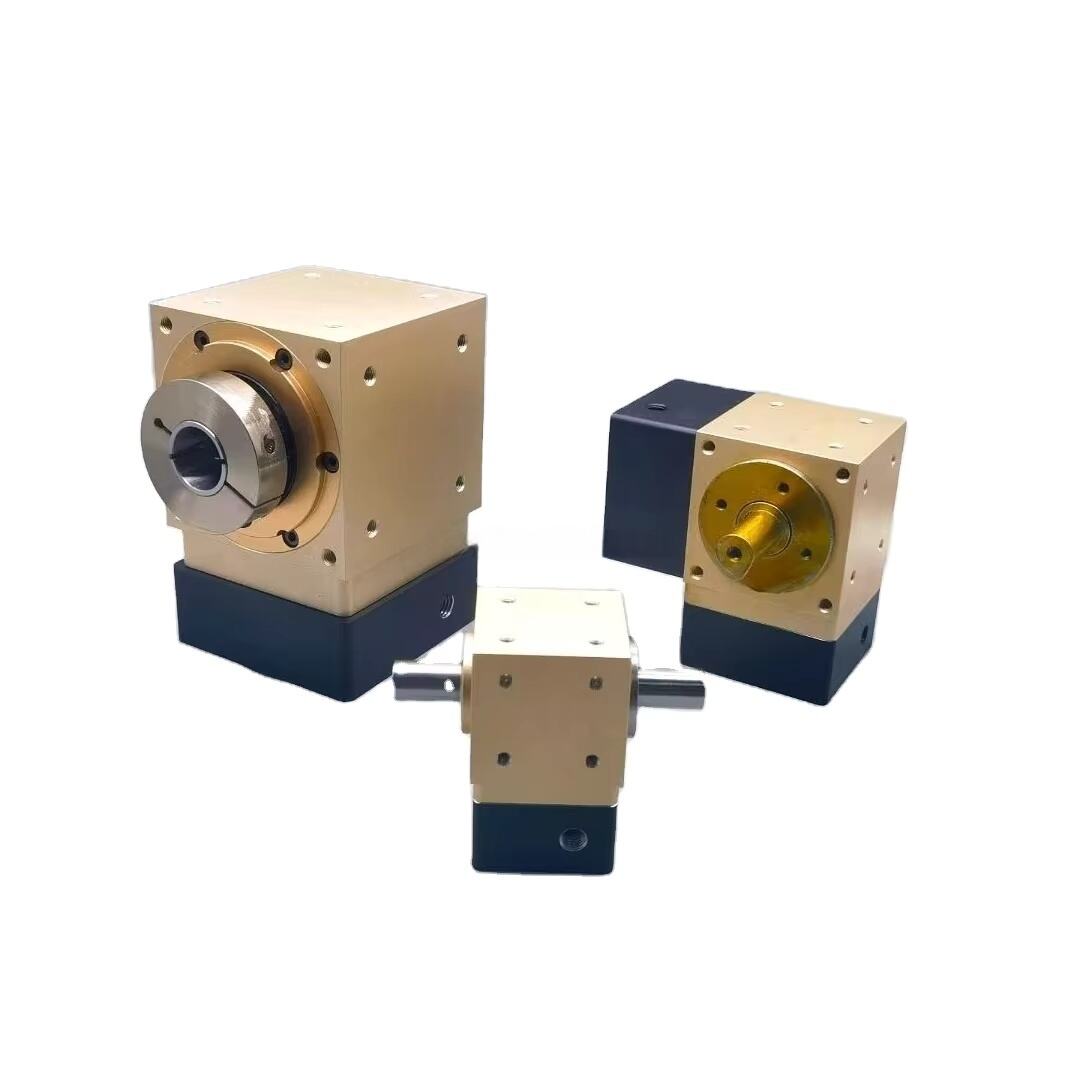

20 1 gear reducer

The 20 1 gear reducer represents a vital piece of mechanical engineering that provides precise speed reduction while maintaining optimal torque output. This efficient device operates on a straightforward principle, reducing input speed by a factor of 20 while proportionally increasing torque. The robust construction features high-grade steel gearing components, precision-machined housing, and advanced sealing technology to ensure reliable performance in various industrial applications. The reducer incorporates helical gearing geometry that promotes smooth operation and minimal noise generation, while its compact design allows for easy integration into existing mechanical systems. The device maintains excellent efficiency ratings, typically above 95 percent, minimizing power loss during operation. Essential features include reinforced bearing supports, optimized lubrication channels, and thermal management systems that contribute to extended service life. The 20 1 gear reducer finds extensive applications in manufacturing equipment, conveyor systems, packaging machinery, and various automated production lines where precise speed control and high torque requirements are critical. The unit's versatile mounting options and standardized input/output configurations make it compatible with a wide range of motors and driven equipment, ensuring maximum flexibility in system design and implementation.