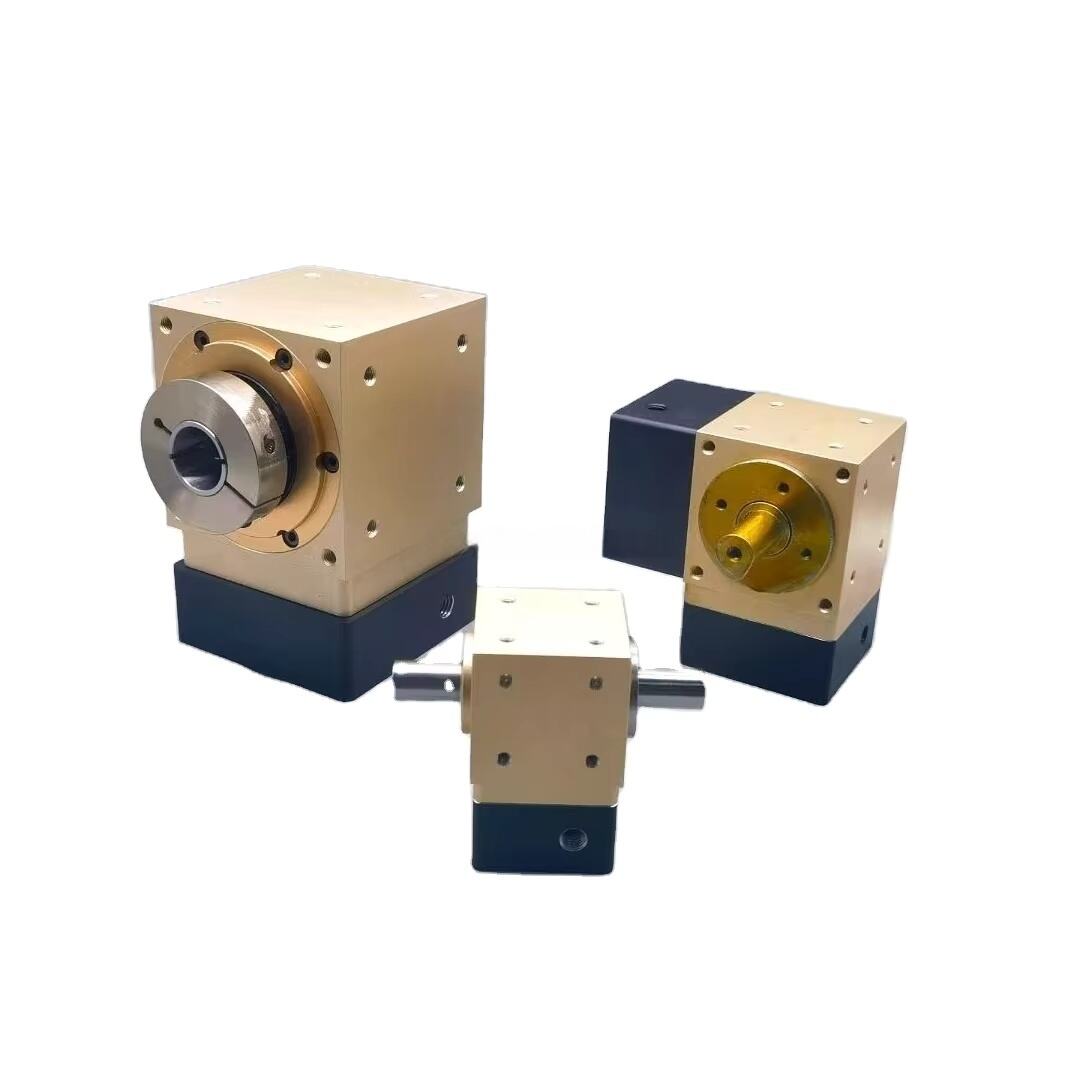

reduction gearbox for sale

A reduction gearbox represents a crucial mechanical component designed to efficiently decrease rotational speed while simultaneously increasing torque output. These precision-engineered devices feature a sophisticated arrangement of gears that work in harmony to achieve optimal power transmission. The gearbox incorporates hardened steel gears, premium bearings, and a robust housing designed for durability and consistent performance. With multiple reduction ratios available, these units can accommodate various industrial applications, from manufacturing equipment to conveyor systems. The gearbox's modular design allows for easy maintenance and replacement of components, ensuring long-term reliability. Advanced sealing technology prevents lubricant leakage and protects against environmental contamination, while the precision-machined gear teeth ensure smooth, quiet operation with minimal vibration. These units are available in various mounting configurations, including foot-mounted, flange-mounted, and shaft-mounted options, providing flexibility in installation. The gearbox's thermal efficiency is enhanced through optimized housing design and superior lubrication systems, allowing for extended operation without overheating.