درک سیستمهای کاهش دنده در تولید مدرن

در محیط پرسرعت امروزی تولید، دستیابی به کنترل دقیق عملیات مکانیکی برای حفظ بهرهوری و کارایی امری حیاتی است. یک جعبه کاهش سرعت به عنوان یک جزء ضروری در سیستمهای اتوماسیون عمل میکند و امکان تنظیم سرعت و گشتاور را جهت تطبیق با نیازهای خاص کاربردی فراهم میآورد. این دستگاههای تخصصی به تولیدکنندگان کمک میکنند تا خطوط تولید خود را بهینهسازی کنند و در عین حال عملکرد قابل اعتماد و بازدهی انرژی را تضمین نمایند.

هنگامی که یک جعبه کاهش دنده به درستی در یک خط اتوماسیون ادغام شود، میتواند ورودی با سرعت بالا و گشتاور پایین را به خروجی کندتر اما قدرتمندتر تبدیل کند. این قابلیت آن را به دارایی ارزشمندی برای کاربردهای صنعتی مختلف، از سیستمهای نقاله تا تجهیزات بستهبندی تبدیل میکند. درک نقش و مزایای این سیستمها برای تصمیمگیری آگاهانه در مورد زیرساخت اتوماسیون شما ضروری است.

مؤلفههای اصلی و عملکرد

اجزای اساسی یک سیستم کاهش دنده

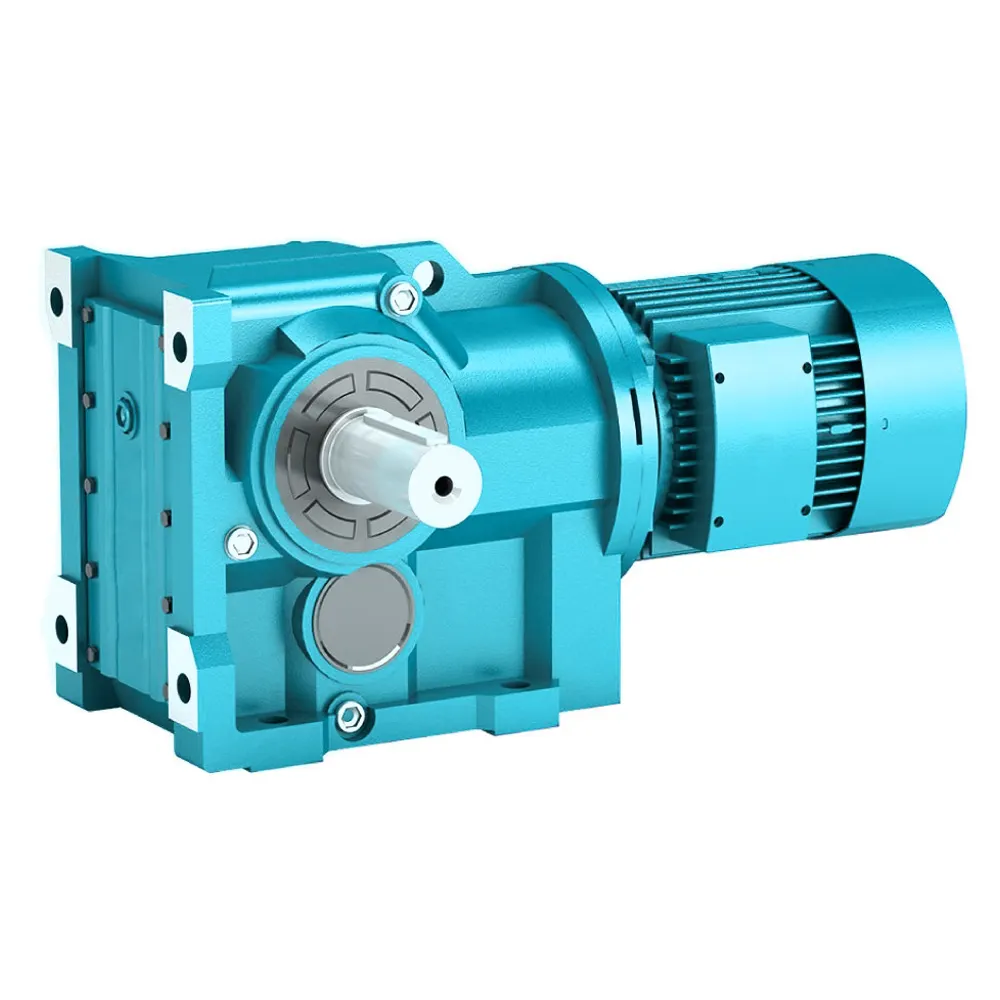

در قلب هر جعبه کاهش دنده، چیدمانی پیچیده از اجزای مکانیکی قرار دارد. عناصر اصلی شامل محورهای ورودی و خروجی، مجموعههای چندگانه دنده، یاتاقانها و یک پوسته محافظ است. هر مجموعه دنده از دندانههای دقیقی تشکیل شده که به صورت هماهنگ با یکدیگر درگیر میشوند تا نسبت کاهش مطلوب ایجاد شود. پوسته نه تنها این اجزای داخلی را محافظت میکند، بلکه روغنرسانی و خنکسازی مناسب را نیز فراهم میکند تا قابلیت اطمینان طولانیمدت تضمین شود.

سیستمهای پیشرفته کاهش دنده ممکن است ویژگیهای اضافی مانند پرههای خنککننده، سنسورهای دما و آببندیهای تخصصی برای جلوگیری از آلودگی را دربرگیرند. این اجزا به صورت هماهنگ کار میکنند تا عملکرد بهینه را در شرایط مختلف کاری حفظ کنند و جعبه کاهش دنده را به راهحلی مقاوم برای محیطهای صنعتی پرمخاطره تبدیل کنند.

اصول عملکرد و مکانیک

اصل اساسی جعبه کاهش دنده، مبتنی بر رابطه ریاضی بین اندازه دندهها و سرعت چرخشی است. هنگامی که یک دنده کوچکتر، دنده بزرگتری را به حرکت درمیآورد، سرعت خروجی کاهش یافته و گشتاور به صورت متناسب افزایش مییابد. این رابطه به تولیدکنندگان اجازه میدهد تا دقیقاً نیازهای سرعت و نیروی مورد نیاز خود را برای کاربردهای خاص فراهم کنند.

سیستمهای مدرن کاهش دنده از انواع مختلف دنده از جمله دندههای مستقیم، مارپیچ و آرایش سیارهای استفاده میکنند. هر طراحی مزایای منحصر به فردی از نظر بازده، کاهش نویز و ظرفیت بار ارائه میدهد. انتخاب نوع دنده و نسبت کاهش، به عواملی چون محدودیتهای فضایی، نیازهای توان و پارامترهای عملیاتی بستگی دارد.

مزایا برای اتوماسیون صنعتی

کنترل و دقت افزایش یافته

اجرا کردن جعبه کاهش دنده در خط اتوماسیون شما، کنترل بیسابقهای بر روی عملیات مکانیکی فراهم میکند. با کاهش سرعت و افزایش گشتاور، این سیستمها امکان کنترل دقیق موقعیتیابی و حرکت را فراهم میکنند که برای کاربردهایی که به زمانبندی یا موقعیتگیری دقیق نیاز دارند ضروری است. این دقت افزایشیافته منجر به بهبود کیفیت محصول و کاهش ضایعات در فرآیندهای تولید میشود.

توانایی تنظیم دقیق سرعت خروجی همچنین امکان همگامسازی بهتر بین اجزای مختلف سیستم اتوماسیون شما را فراهم میکند. این همگامسازی برای حفظ عملیات روان و جلوگیری از ایجاد گلوگاه یا آسیب به تجهیزات ناشی از عدم تطابق سرعتها بسیار مهم است.

بهره وری انرژی و صرفه جویی در هزینه

یک جعبه کاهش دنده بهدرستی مشخصشده میتواند بهطور قابل توجهی بازده انرژی خط اتوماسیون شما را بهبود بخشد. با تطبیق خروجی موتور با نیازهای واقعی بار، این سیستمها هدررفت انرژی را به حداقل میرسانند و هزینههای عملیاتی را کاهش میدهند. افزایش ظرفیت گشتاور همچنین بدین معناست که برای بسیاری از کاربردها میتوان از موتورهای کوچکتر و کارآمدتر از نظر مصرف انرژی استفاده کرد.

مزایای هزینهای بلندمدت فراتر از صرفهجویی در انرژی است. کاهش تنش واردشده به موتورها و سایر اجزای مکانیکی منجر به نیاز کمتر به نگهداری و عمر طولانیتر تجهیزات میشود. این دوام به معنای تعویض کمتر و کاهش توقفهای تولید است که به سود عملیاتی بهتر منجر میشود.

معیارها و ملاحظات انتخاب

تحلیل نیازهای کاربرد

قبل از انتخاب جعبه کاهش دنده، انجام تحلیل دقیقی از نیازهای کاربرد شما ضروری است. این تحلیل شامل ارزیابی عواملی مانند سرعت خروجی مورد نیاز، نیازهای گشتاور، چرخه کاری و شرایط محیطی میشود. درک این پارامترها تضمین میکند که سیستم انتخابشده هم به نیازهای فعلی و هم امکان گسترش آینده پاسخ دهد.

محدودیتهای فیزیکی فضای نصب و هرگونه نیاز خاص در مورد نصب را در نظر بگیرید. جعبه کاهش دنده باید بهصورت یکپارچه با تجهیزات موجود کار کند و در عین حال دسترسی مناسب برای نگهداری فراهم کند. همچنین، هرگونه مقررات یا استانداردهای خاص صنعت را که ممکن است بر انتخاب شما تأثیر بگذارند، لحاظ کنید.

مشخصات و ردهبندی عملکرد

هنگام ارزیابی گزینههای کاهش دنده، به دقت به مشخصات کلیدی عملکرد مانند نسبت کاهش، رتبهبندی بازده و ظرفیت حرارتی توجه کنید. نسبت کاهش باید با نیازهای سرعت شما هماهنگ باشد و در عین حال سطح بازده قابل قبولی حفظ شود. رتبهبندیهای حرارتی به ویژه برای کاربردهای پیوسته مهم هستند که در آنها تجمع گرما میتواند بر عملکرد تأثیر بگذارد.

عامل سرویس و ویژگیهای بار کاربرد خود را در نظر بگیرید. برای کاربردهایی که شامل راهاندازیها و توقفهای مکرر یا بارهای ضربهای سنگین هستند، ممکن است عامل سرویس بالاتری لازم باشد. درک این مشخصات تضمین میکند که جعبه کاهش دنده انتخابی شما عملکرد قابل اعتمادی در شرایط واقعی کاری فراهم کند.

سوالات متداول

جعبه کاهش دنده چند وقت یکبار باید نگهداری شود؟

فاصلههای معمول نگهداری و تعمیرات عمدتاً به شرایط کارکرد و توصیههای سازنده بستگی دارد. به طور کلی، سطح روغن باید هر ماه بررسی شود و تعویض کامل روغن سالانه یا پس از هر ۲۵۰۰ ساعت کارکرد انجام گیرد. بازرسیهای بصری برای تشخیص نشتی و صداهای غیرعادی باید هفتگی انجام شود، در حالی که بازرسیهای جامعتر ممکن است هر سه ماه یکبار برنامهریزی شوند.

چه نشانههایی نشان میدهند که جعبه کاهش دنده نیاز به تعویض دارد؟

نشانههای کلیدی شامل سر و صدای زیاد یا لرزش، نشت روغن، افزایش دمای کارکرد و کاهش عملکرد یا دقت است. پایش منظم این پارامترها میتواند به شناسایی مشکلات احتمالی قبل از خرابی سیستم کمک کند. اگر هر یک از این نشانهها را مشاهده کردید، انجام یک بازرسی دقیق و مشورت با یک تکنسین واجد شرایط مهم است.

آیا میتوان جعبه کاهش دنده را به تجهیزات موجود اضافه کرد؟

بله، معمولاً میتوان جعبههای کاهش دنده را به تجهیزات موجود اضافه کرد، مشروط بر اینکه برنامهریزی مناسب و ملاحظات مهندسی در نظر گرفته شود. این امر شامل تضمین پیکربندیهای نصب سازگار، ترازبندی صحیح و اتصالات مناسب انتقال قدرت میشود. همکاری با تأمینکنندگان یا مهندسان مجرب میتواند به تضمین نصب موفقیتآمیز در حین اصلاح مجدد کمک کند.