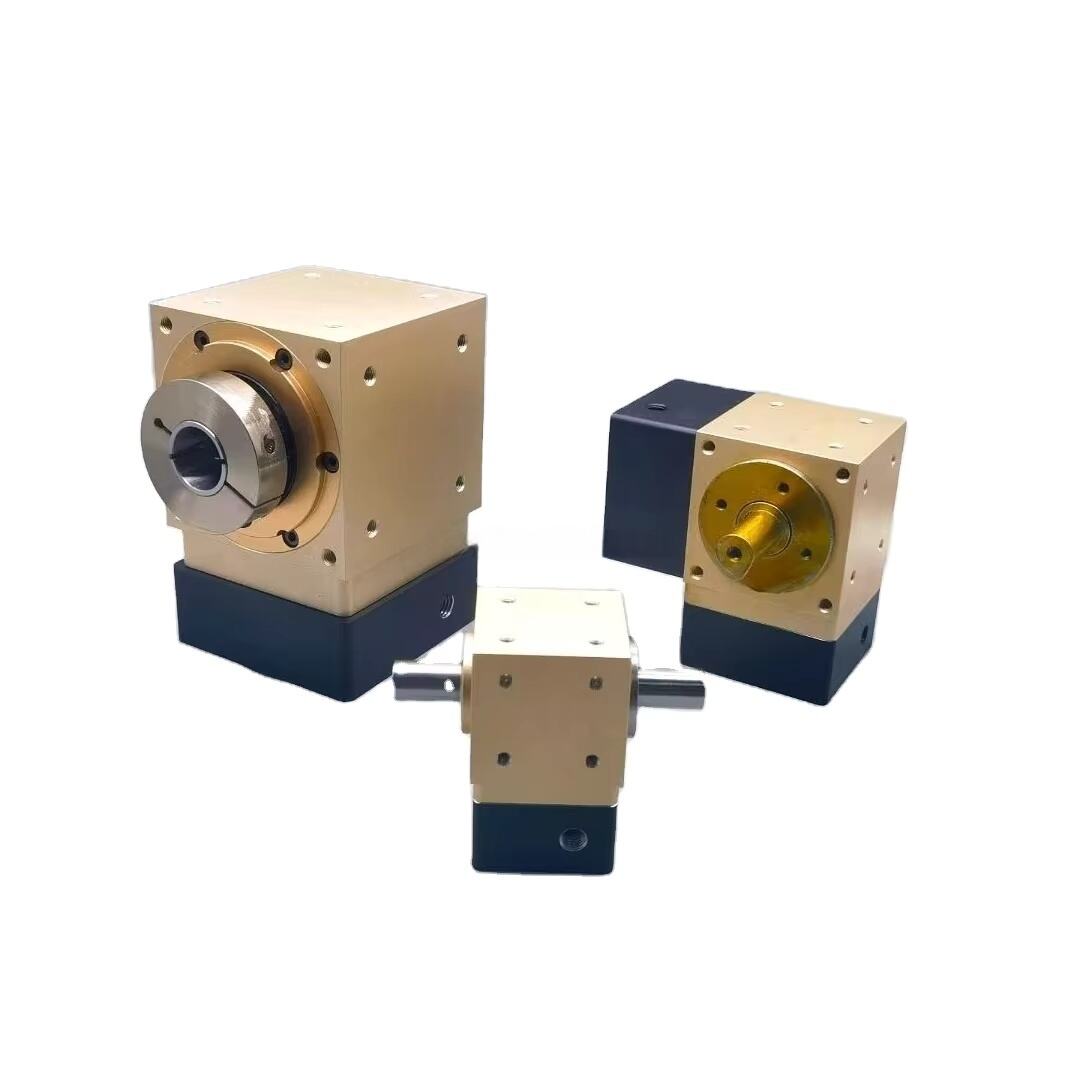

hub city gear reducer

The Hub City gear reducer represents a pinnacle of power transmission engineering, designed to efficiently convert high-speed, low-torque power into low-speed, high-torque output. This essential industrial component features precision-engineered gearing systems housed within a robust cast iron or aluminum casing, ensuring optimal performance and longevity. The reducer employs helical, spur, or worm gear configurations, depending on the specific application requirements, providing smooth and reliable operation across various speed ratios. A key technological feature is its modular design, allowing for flexible mounting options and easy maintenance. The unit incorporates advanced sealing systems to prevent lubricant leakage and protect against environmental contaminants, while its thermal management capabilities ensure stable operation under demanding conditions. Hub City gear reducers find widespread applications across numerous industries, including manufacturing, material handling, food processing, and agricultural equipment. The units are particularly valued in conveyor systems, packaging machinery, and heavy-duty industrial equipment where precise speed control and torque multiplication are crucial. Their compact design and high-efficiency rating make them ideal for applications where space is limited but power requirements are substantial.