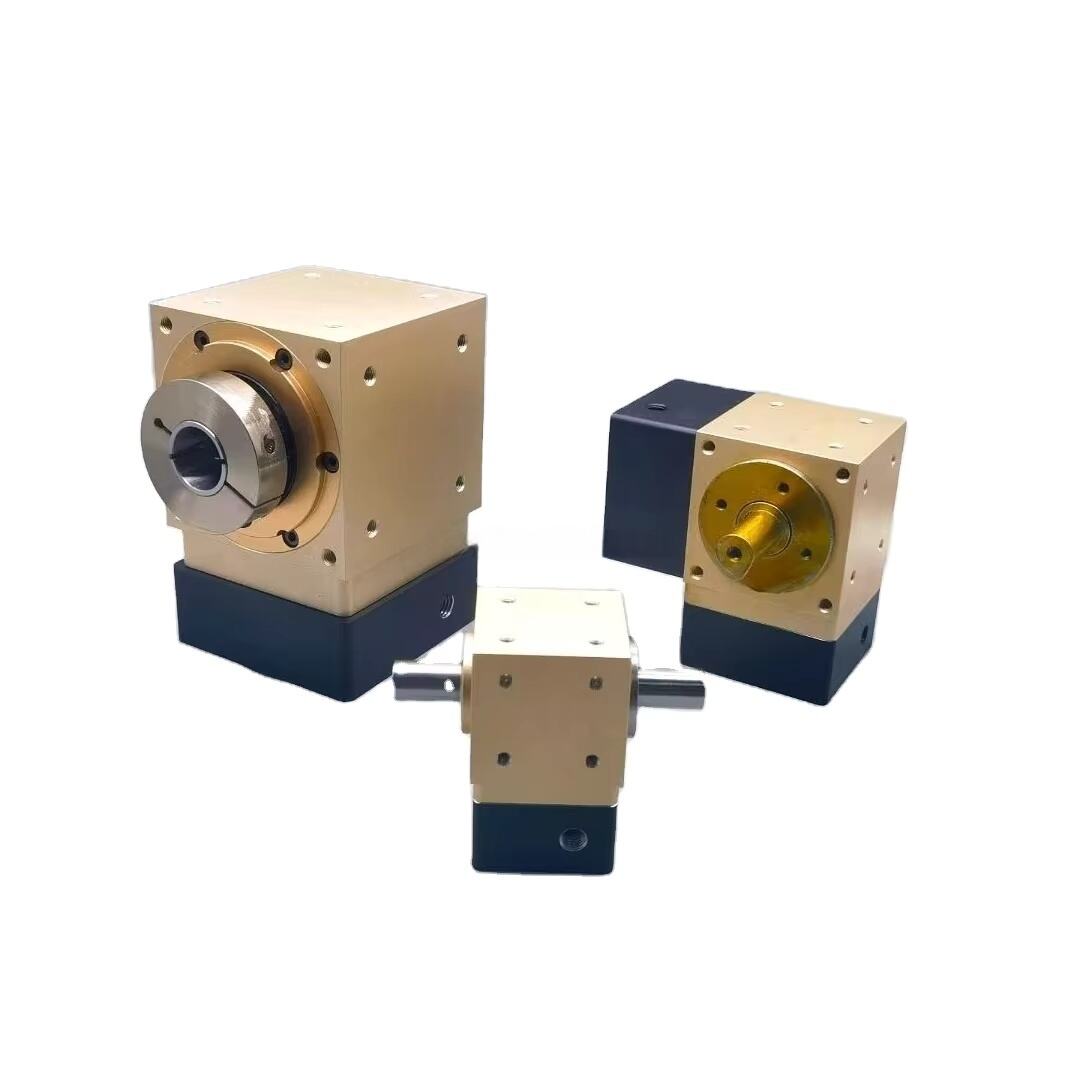

56c gear reducer

The 56c gear reducer represents a crucial advancement in power transmission technology, offering precise speed control and torque multiplication for industrial applications. This robust device efficiently converts high-speed, low-torque motor input into lower-speed, higher-torque output, making it essential for various manufacturing and processing operations. The 56c designation specifically refers to the NEMA motor frame size compatibility, ensuring standardized mounting dimensions for seamless integration with existing systems. Engineered with premium-grade materials, this gear reducer features hardened steel gears, precision-ground tooth profiles, and sophisticated sealing systems that prevent lubricant leakage while protecting against environmental contaminants. The unit's compact design maintains optimal efficiency while reducing space requirements, and its modular construction facilitates easy maintenance and component replacement when necessary. With multiple reduction ratios available, the 56c gear reducer can be tailored to meet specific application requirements, whether in conveyor systems, packaging equipment, or material handling machinery. The reducer's thermal capacity is enhanced through optimized housing design and superior lubrication systems, ensuring reliable performance even under continuous operation.